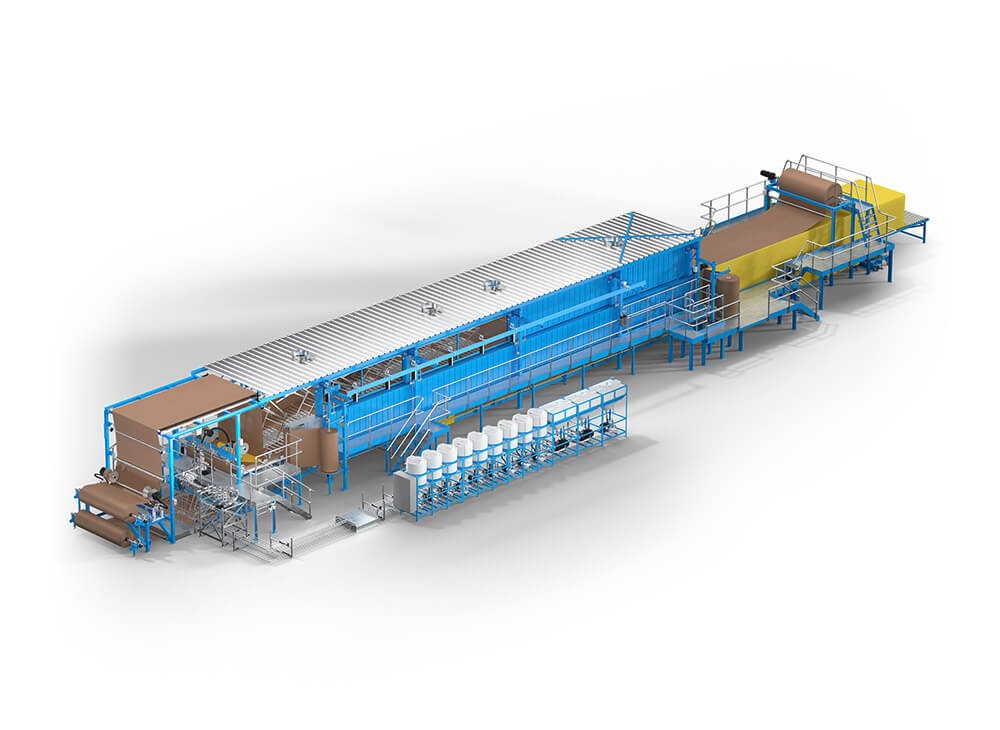

A new generation makes its debut: With the SMARTFLEX evo, Hennecke presents a consistent further development of its proven plant concept for continuous slabstock foam production. The new system complements the portfolio between the compact JFLEX evo and the high-performance MULTIFLEX – and opens up new possibilities for users to economically enter the industrial production of comfort foams.

A new chapter in the Hennecke’s slabstock foam portfolio

With the SMARTFLEX evo, Hennecke is expanding its range in the field of continuous slabstock foam production. The system closes the gap between the JFLEX evo – designed for small to medium production volumes – and the MULTIFLEX, which is regarded worldwide as the benchmark for productivity. “With the SMARTFLEX evo, we offer our customers a solution that combines all the key design and technological advantages from more than 70 years of experience in continuous slabstock foam production. At the same time, the system gives foam producers in the furniture and mattress industry an economically attractive entry into higher production volumes,” explains Svend Weidemann, President of the Hennecke Business Unit Germany. “We have thereby created an attractive gateway to large-scale foam production – efficient, functional, and designed for the future.”

Focus on comfort foams

The SMARTFLEX evo was developed specifically to meet the requirements of comfort foam applications – for example mattresses, upholstered furniture, or other applications in the home and furniture sector. “For technical foams, as we define them, MULTIFLEX or QFM remain the recommended systems,” explains Dr. Joachim Berthold, Senior Director Sales Molded Foam, Slabstock & Technical Insulation. “For users in the comfort segment, however, the SMARTFLEX evo is a perfectly tailored solution that combines high efficiency with proven Hennecke quality.”

Technology meets cost-efficiency

The SMARTFLEX evo offers an impressive balance between performance and investment cost. The aim was to create an attractively priced alternative to the MULTIFLEX – without compromising on quality. “We defined the technical parameters – particularly with regard to viscosity and output – in such a way that they cover a large number of typical application scenarios,” explains Dr. Florian Thiebes, Team Leader Mechanical Design Slabstock. “The result is a system that combines high productivity with an efficient use of resources – creating real added value for our customers.”

Modular design – Compact in concept, flexible in execution

As with the MULTIFLEX and QFM, the system concept of the SMARTFLEX evo also impresses with its consistently modular, yet particularly space-saving design. A high degree of standardization helps to reduce investment costs for producers. The absence of a classic portal significantly reduces the overall height – a clear advantage where hall heights are limited. At the same time, the modular design enables short delivery times and rapid commissioning. For example, the modules can be transported in larger assemblies, which can significantly reduce assembly times at the customer’s premises.

High-pressure technology as standard

The SMARTFLEX evo retains one central feature: the high-pressure metering of all isocyanates. “Precise high-pressure metering is an integral part of the SMARTFLEX evo and ensures optimum raw material utilization and excellent foam quality,” explains Dr. Thiebes. Compared to low-pressure systems, isocyanate savings of up to four percent can be achieved – a clear efficiency advantage. Hennecke also relies on proven technology for the application process, but in a revised arrangement: The indirect liquid laydown process feeds the material from the permanently installed mixer to the application table via a short, flexible hose. A technical innovation here is the MIXGUIDE deflection plate. This moving paper guide prevents the material from flowing back and ensures a homogeneous foaming reaction of the discharged mixture across the entire foaming width. This is particularly advantageous for quick formulation changes, as waste is effectively avoided. The effective prevention of production waste is a hallmark of all Hennecke slabstock foam systems. Unlike trough systems, the SMARTFLEX evo also impresses with significantly lower waste quantities and considerably minimized cleaning effort when changing formulations, significantly improving cost-efficiency.

High flexibility and efficiency

The SMARTFLEX evo enables the processing of up to eight polyols, three isocyanates, and 24 additives. The metering pump units are optimally matched to common viscosities and output capacities. The new SMARTJECTOR injection units and the optional computer-monitored volume flow measurement of safety-relevant components ensure maximum precision. As a special feature, the system includes manually tiltable side walls as standard – optionally available with motorized adjustment. These allow precise adaptation to different foam types and, in combination with the standard FLAT-TOP system, enable an almost rectangular block shape. The result: less waste on the foam block and a significantly improved raw material yield. The SMARTFLEX evo also features an ergonomically optimized operator platform that provides improved access around the mixer for production and servicing.

Comprehensive control

Like all new slabstock lines from Hennecke, the SMARTFLEX evo is equipped with the intuitive FOAMWARE Slabstock visualization and control software. The software runs on a powerful SIMATIC industrial PC and enables fast commissioning, efficient process control, and the complete management of production data – including remote servicing. Additional options are available for advanced requirements: for example, block height and Rise Profile Measurement with additional sensors for enhanced process reliability.

Technology that convinces

With the SMARTFLEX evo, Hennecke has set another milestone in the polyurethane industry. The system combines proven high-performance technologies with a compact, modular design – at an economically attractive price. “Our customers receive a state-of-the-art, efficient solution that opens the door to the premium comfort foam market – and benefits from the many technological strengths of Hennecke’s state-of-the-art systems,” emphasizes Dr. Berthold. The SMARTFLEX evo thus offers a perfect entry into large-scale industrial production – consistently developed and future-oriented.