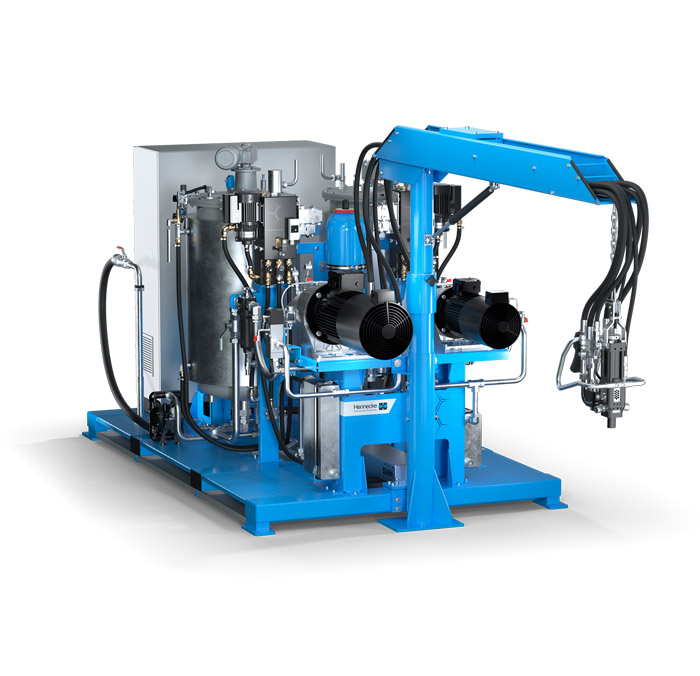

TOPLINE MK2

NOVITÀ The new TOPLINE MK2 is the crowning highlight of Hennecke's Next Generation series. The premium high-pressure metering machine covers all conceivable PU applications. This is the case too when it comes to highly demanding raw material systems typically requiring the most exact temperature control possible. It is also the first choice for highly automated applications such as refrigerated furniture production, seat foams or exterior and interior components for vehicle production. The TOPLINE MK2 is used as a stand-alone solution or in all conceivable system configurations where the highest quality, the greatest possible production and process stability as well as automation and scalability are required. Alongside powerful basic equipment, it offers maximum flexibility and adapts to even the most complex process requirements thanks to numerous optional modules:

- The TOPLINE MK2-platform can be equipped with up to ten mixheads. Almost all Hennecke mixheads are available for this purpose: from the MT 3 for low output rates and the smallest part weights to the MT 36-2 for extremely high output rates, multi-component mixheads such as the MT-A 22-4, the MN series for spray applications and the new MT 12-3 CC color-changing mixhead. Of course, the TOPLINE MK2 portfolio also includes a wide variety of sizes from the top MT-A series, both for open shot and for docked processing.

- In combination with the FIXJET and FLEXJET (SL and GL type) series from the latest Hennecke injector generation, the TOPLINE MK2 mixhead portfolio outperforms in fulfilling all the requirements of modern polyurethane systems in terms of metering accuracy, mixing quality and service life of the components.

- The groundbreaking HX pump is significantly more pressure-resistant, quieter, and more energy-efficient than other common pump models. In addition, integrated sensor technology gives the user extensive information when required, and supports improved machine availability through predictive maintenance.

- The TOPLINE MK2 features a hose line system that allows full flexibility for positioning the mixhead, for example when used on an optional boom. Here, too, the TOPLINE MK2 offers the greatest possible flexibility: instead of the 3-meter standard boom, other booms with a longer reach or automated mixhead handling through the use of robotics via an automatic interface are also available.

- The TOPLINE MK2 is controlled using the latest SIMATIC platform components. The high-resolution, 12-inch premium HMI with powerful CPU is home to a completely new and intuitive visualization system: the Hennecke FOAMATIC. The operator can be sure of maximum performance and control, along with fast access for the widest range of applications in many common languages. Remote HMI allows the FOAMATIC to mirror the user interface on almost any network-compatible device with a display.

- The TOPLINE MK2 enables connection to the Internet of Things with the FOAMATIC-IoT equipment feature. The acquisition and storage of extensive process data offers Hennecke customers unimagined possibilities for evaluation, early detection and prevention of problems, as well as predictive machine maintenance.

- As a "high performance" machine, the TOPLINE MK2 allows upgrading with numerous options. Thanks to the modular design of the multi-platform construction with separate tank station (modular-frame design), larger work tanks with a volume of up to 1,000 liters are available for large-scale production, as are 60-liter versions for smaller components or quantities. The newly developed TS5evo temperature control unit and specially adapted control software play a key role in ensuring a constant raw material temperature, even with the most adverse production conditions. This enables powerful and constant temperature control – even under the most difficult processing conditions. A reliable stirrer with an optional magnetic coupling also ensures a homogenous temperature distribution inside the tank even without running the metering pumps.

NEXT-GEN metering machines are fitted with Hennecke's Blue Intelligence technology as standard, which also makes them significantly more energy-efficient. The TOPLINE MK2 also benefits from Hennecke's Blue Intelligence technology – the latter comprising a whole package of measures for mechanical, hydraulic and thermal efficiency. This includes optimized components to reduce pressure drops, automatically determined pump lead times, intelligent standby timers, efficient pumps and much more. Based on the individual production scenario, savings of up to 50 percent can be made with the TOPLINE MK2, even in its standard configuration.

#nextgenstore

The world's first configuration platform for metering machines.

Qui sono disponibili contenuti di accompagnamento in formato PDF

Per la valutazione è necessario Adobe Reader®, scaricabile gratuitamente qui.

Tutte le macchine dosatrice ad alta pressione in breve

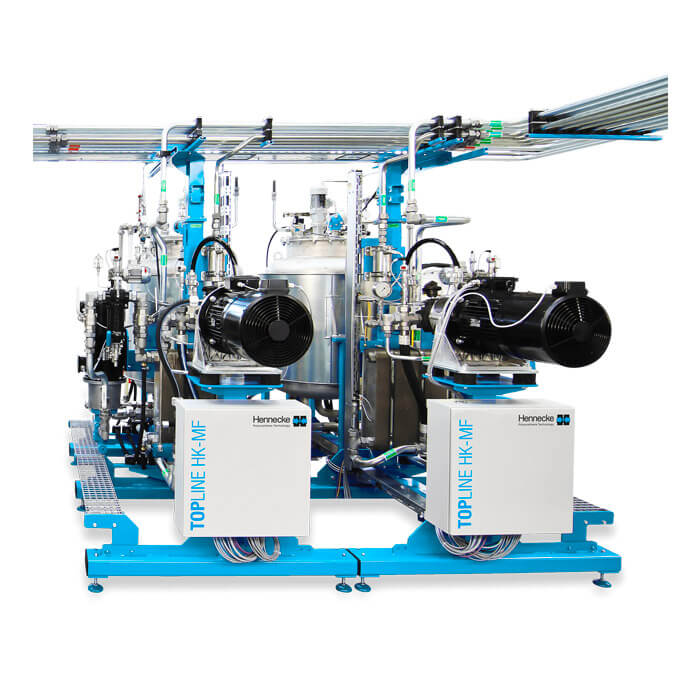

TOPLINE HK

Macchine dosatrici modulari ad alta pressione per infinite applicazioni

disponibile.

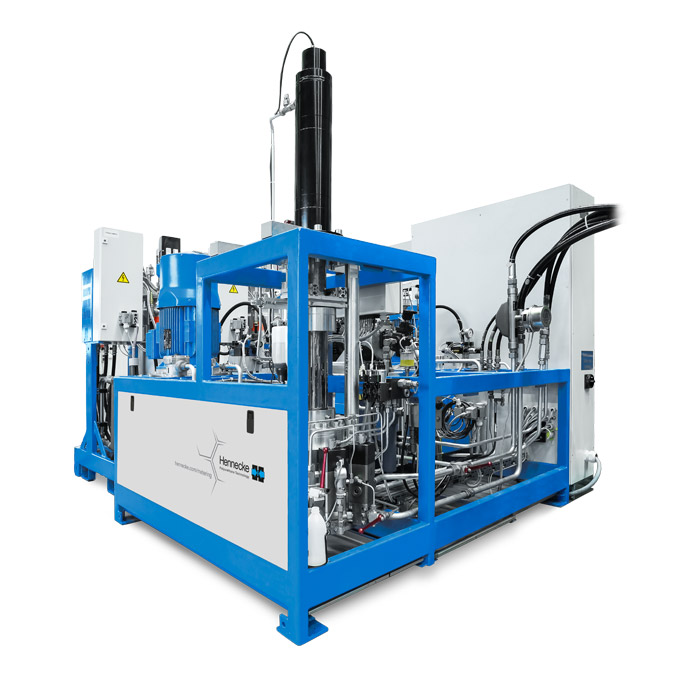

HIGHLINE

Macchine dosatrici ad alta pressione compatte per un'ampia gamma di applicazioni

disponibile.

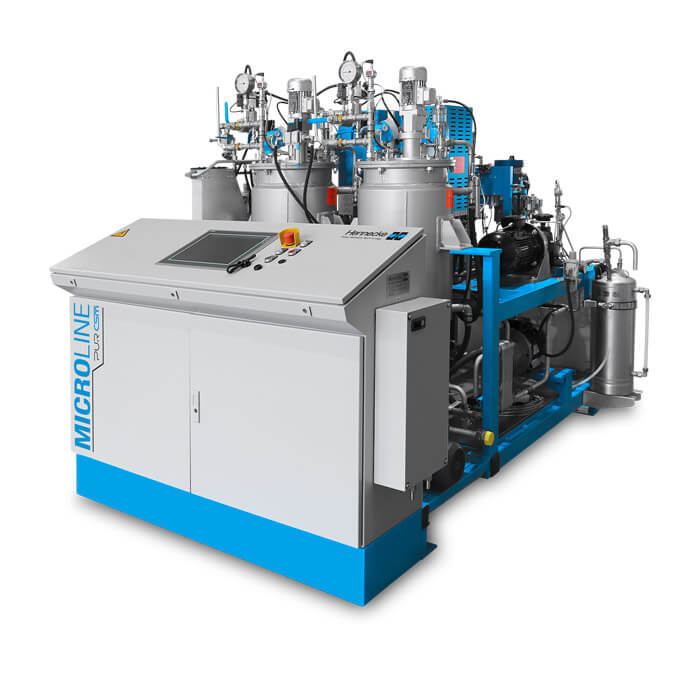

ECOPLUS

Macchine dosatrici ad alta pressione compatte per numerose possibilità di applicazioni standard

disponibile.

TOPLINE HK-TI

Macchina dosatrice ad alta pressione per la produzione di dispositivi di raffreddamento e applicazioni nel campo dell'isolamento termico

disponibile.