FOAMWARE Slabstock: Precision and process stability for continuous slabstock foam production

Optimized for complex polyurethane systems

FOAMWARE Slabstock is tailored to the specific requirements of continuous slabstock foam production. It is based on the modular FOAMWARE platform and provides a reliable, expandable control environment for processing complex polyurethane systems.

Thanks to its specifically adapted architecture, the software supports consistently high product quality and efficient process control—an important advantage when raw material parameters or environmental conditions such as temperature fluctuate. The software architecture enables precise control of complex reaction processes and forms the basis for uniform material distribution, reproducible foam heights, and reduced scrap rates. Plant operators benefit from stable processes and the ability to integrate additional measuring and control systems.

Specific functions for slabstock applications

- RISE PROFILE MEASUREMENT: Prepared for the optionally available sensor system for visualizing foam height at up to 30 measurement points during the rise process, enabling optimal density distribution.

- AUTO-FLAT system: Designed for optional use of the AUTO-FLAT system to automatically generate a flat, reproducible foam surface—independent of operator influence. This increases process stability and reduces material waste.

- “Magic Eye” function: Detects metering deviations during operation and enables immediate intervention.

- Tunnel depth control: Precise control of tunnel depth enables uniform reaction behavior and optimized material distribution.

- Customized plug-ins: Slabstock-specific add-on functions such as layout manager and individually configurable quick links simplify operation during production.

Customer benefits at a glance

- High and consistent production quality under variable process conditions

- Reduced scrap and lower raw material consumption

- Fast response to deviations in temperature, humidity, or activators through targeted visualization

- Software-side integration of prepared measuring and control systems

- Expandability for future requirements and system adaptations

FOAMWARE Complete Care

The FOAMWARE Complete Care service package was developed specifically for the FOAMWARE Slabstock and ensures that the system remains up to date, increases operational reliability, and bundles all necessary services at an affordable price. Regular updates, prioritized support, online training, and a defined hardware replacement schedule ensure stable and supported system operation.

FOAMWARE version 2025

FOAMWARE version 2025 introduces eight new features focused on ease of use, clarity, and data analysis.

New layout management that allows individual layouts to be created, customized, and saved; layouts can be switched within seconds and exported or imported.

Quick-selection bar for significantly faster navigation, with frequently used tools accessible with a single click.

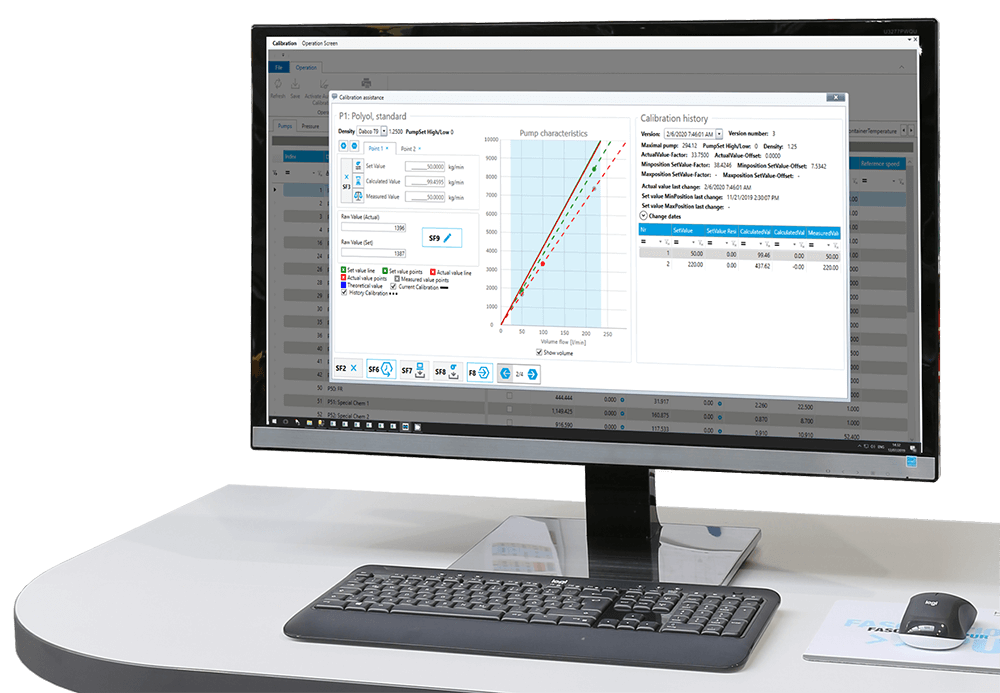

Redesigned calibration screen with improved visibility of relevant elements; pump colors can be edited and the layout now also supports RPM values.

Pump switches can be rearranged via drag-and-drop to improve visibility and can also be organized into color-coded groups.

Simplified data entry with batch numbers and polyol multipliers adjustable on the fly; recipe changes can be canceled at any time; target values of selected pumps can be adjusted via plus/minus buttons; flow control per line can be deactivated during production.

New flow chart visualization showing valve positions and pump status at a glance, with the option to display process values in either mass or volume units.

Jobs can be copied, active and upcoming jobs are immediately visible, and the system can calculate material requirements in advance.

HPA V2 provides standard dashboards for data analytics, offering preconfigured evaluations for structured analysis of production data.