FOAMATIC – intelligent automation for PLC-based production systems

Comprehensive redevelopment of the control system

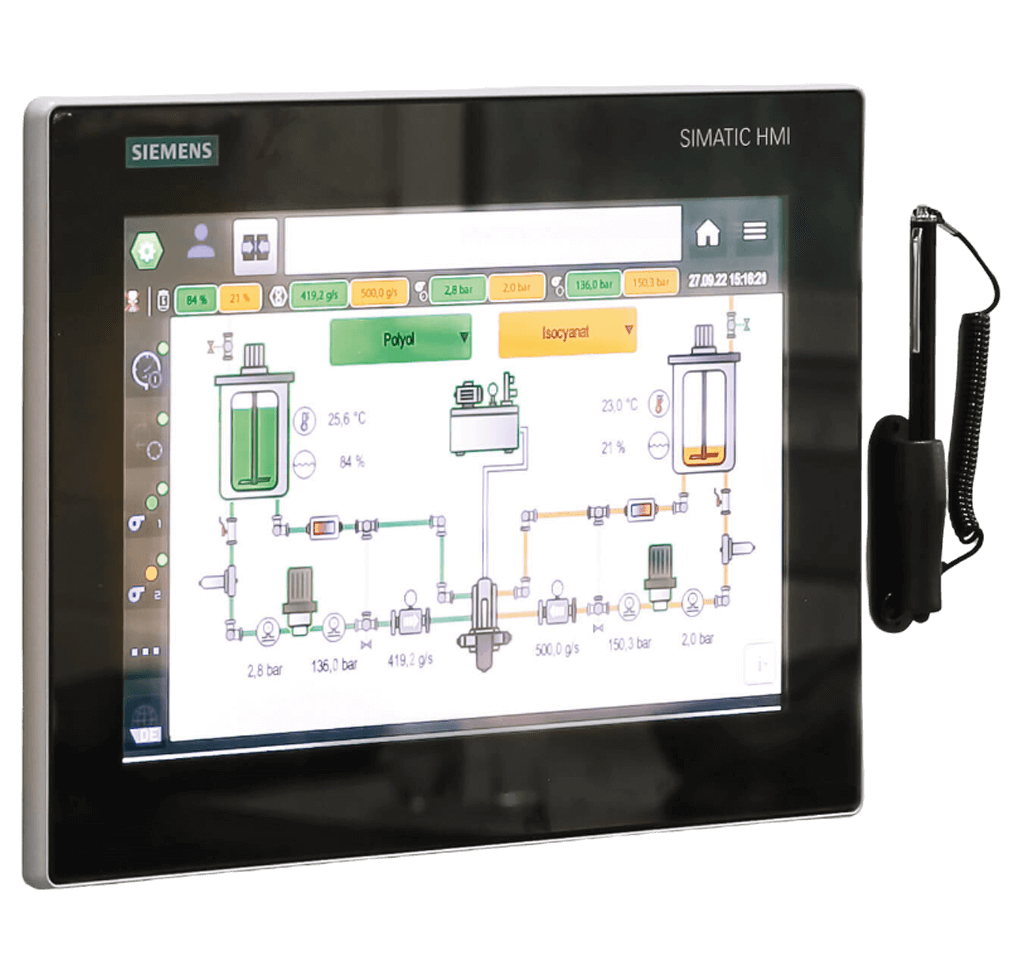

FOAMATIC represents a comprehensive modernization of machine control and replaces legacy systems with a future-oriented platform. The solution combines a modern human-machine interface (HMI) with a redesigned programmable logic controller (PLC) and is used in next-generation metering machines as well as in additional system types in the future.

The goal of the FOAMATIC platform is to make key machine functions intuitively controllable, leverage energy efficiency potential, and sustainably increase production quality and system availability. In addition, FOAMATIC meets all requirements for end-to-end digitalization and is prepared for Industry 4.0 applications.

Modern HMI for intuitive control of all key machine functions

System architecture

HMI – Human Machine Interface

The operating concept is based on high-quality, high-performance touch displays with a graphically guided design and a clear user logic. The so-called “three-click philosophy” allows direct access to all relevant machine parameters with a maximum of three clicks, ensuring particularly simple and intuitive operation. Shortcuts also enable faster input. Physical operating elements on control cabinets are almost completely eliminated in new systems. Via remote HMI functionality and Wi-Fi connectivity, all control data can also be mirrored independent of location.

PLC – Programmable Logic Controller

The control unit has been completely redesigned to implement new functions, higher computing power, and improved energy efficiency. The PLC handles all time-critical machine functions and ensures precise sequence control.

Key functions

- Intuitive, modern user interface with clear user guidance

- Real-time visualization of process states

- Easy parameterization and fast response to process deviations

- Integration into existing production environments possible

- Reduction of operating errors through visual feedback

Benefits of the FOAMATIC control system

- Improved energy efficiency through optimized control logic

- Raw material savings through more precise metering processes based on high-quality control technology

- Increased production quality and process stability

- Faster commissioning thanks to simplified user guidance

- Optimal preparation for digital services and remote maintenance

- Industry 4.0 ready thanks to expandable system architecture

FOAMATIC IoT is the cloud-based solution for collecting, storing, and analyzing production-relevant and process-related data. It increases efficiency, reduces costs, and creates transparency and planning reliability in production.