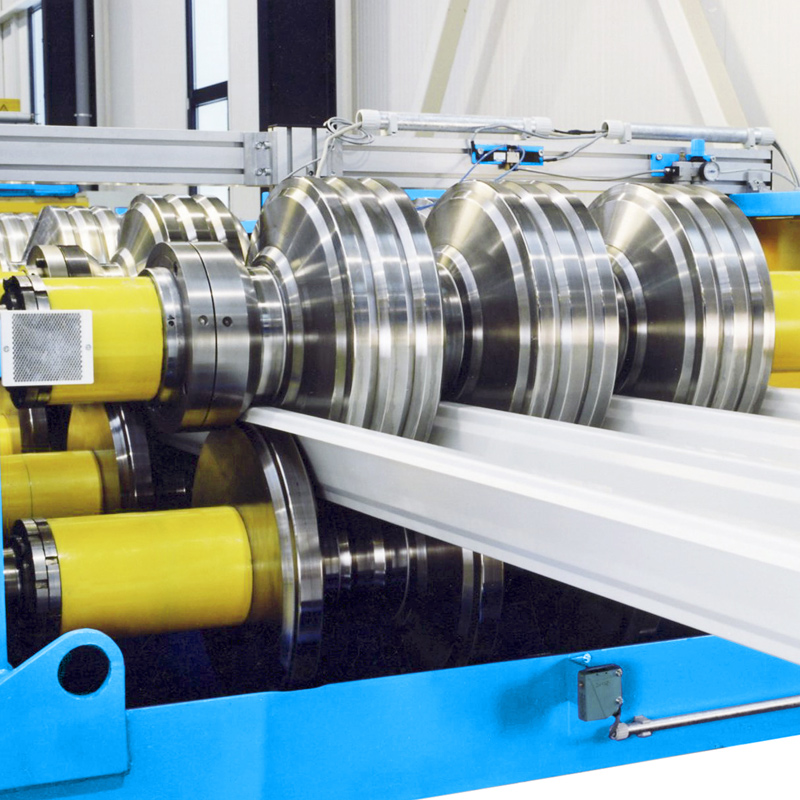

Trapezoidal sheet roll forming lines

The high-performance trapezoidal sheet roll forming plants from Hennecke-OMS facilitate the manufacture of high-quality trapezoidal sheets. There are almost no limits with regard to the profile geometries. All components of the high-performance systems are constructed in such a way that they are highly rigid. This allows our customers to run production within the lowest tolerances. In addition, the high-precision design of our plants ensures excellent repetition accuracy. Furthermore, the high production speed in combination with short set-up times ensures optimum plant efficiency. Our plants are also equipped with the latest PLC automation and high-quality hydraulic components. This guarantees that everyday production runs smoothly in the long term.

Areas of application

Trapezoidal sheet roll forming plants are available for the following applications:

- Single or double-shell trapezoidal facings for roof and wall covering

- Trapezoidal sheets with anti-condensation fleece

- Corrugated sheets for roof and wall cladding

Depending on the layout of the plant, the following primary materials can be used:

- Galvanized sheet steel with a thickness of at least 0.4 millimetres

- Aluminium with a thickness of at least 0.3 millimetres

- Coated and painted primary material

- High-strength primary material grades

- Primary materials with and without protective foil

Highlights and features

Trapezoidal sheet roll forming plants come equipped with the following features right from the factory:

- Coil loading

- Strip preparation

- Strip connection with automatic gluing machines

- Roll forming section for edge and surface profiling, surface lining, surface structuring

- Flying or static separation

- Stacker

- Packer

Get the most out of your production! We offer real distinctive features:

- High precision

- Excellent repetition accuracy

- Very high production speed

- Shortest set-up times

- Optimum plant efficiency

- Tailor-made customer solutions