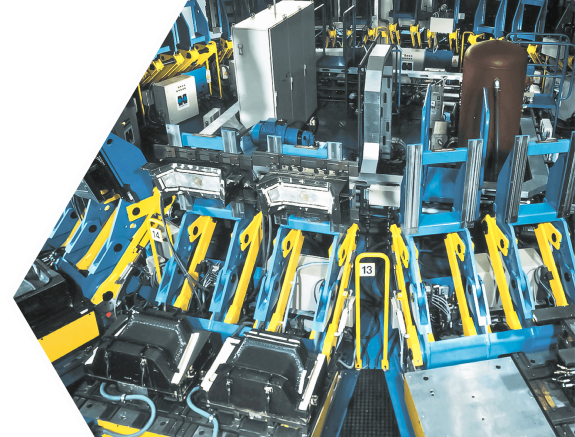

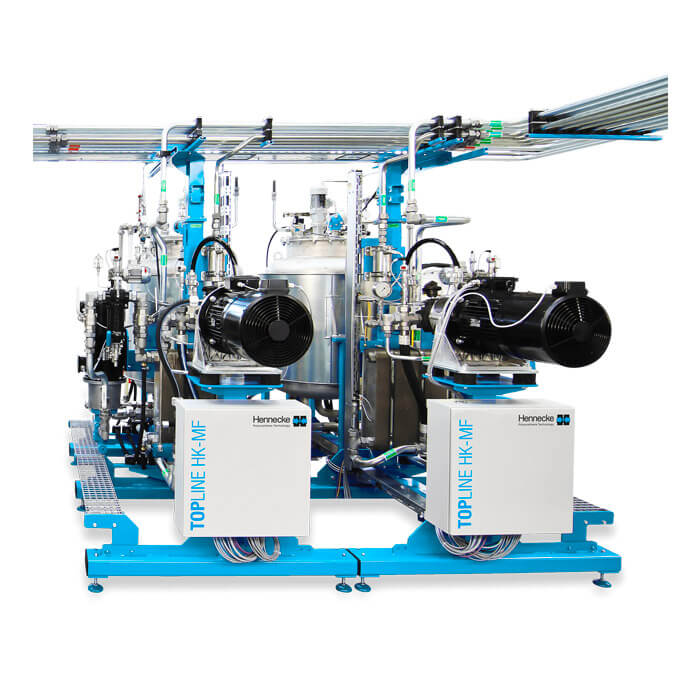

RTN/RTH systems

Hennecke's rotary table systems comprise a circular horizontal conveying unit that accommodates the mold carriers. The technology is suitable for medium to large production volumes. The rotation of the table may be indexed or continuous, depending on process requirements. The cycle length is determined by the molded part having the longest curing or handling time. Hennecke supplies rotary table systems in diverse circumferences. In line with customer needs, they can be combined with automatic filling manipulators, robots and/or electronic logging of production parameters for quality assurance.

Click here for accompanying documents in the PDF format

You will need Adobe® Reader® that you can download here for free.