FOAMWARE Molded Foam: Customized control for highly automated molded foam systems

Precise and cost-efficient control in molded foam production

FOAMWARE Molded Foam is specifically tailored to the requirements of modern, discontinuously operating molded foam systems. It is based on the central FOAMWARE platform and was designed for processes in which polyurethane is introduced into molds in precisely defined metering cycles and patterns—typically pre-mixed and automatically controlled.

The software supports rotary table and oval systems with variable mold occupancy and responds flexibly to different cycle times, quantities, and process stages. FOAMWARE Molded Foam thus forms the technological foundation for precise and economical control of highly automated molded foam applications.

Specific functions for molded foam applications

- Shot pattern management: Integrated configuration and control of recurring metering cycles—time-based, quantity-based, and mold-specific.

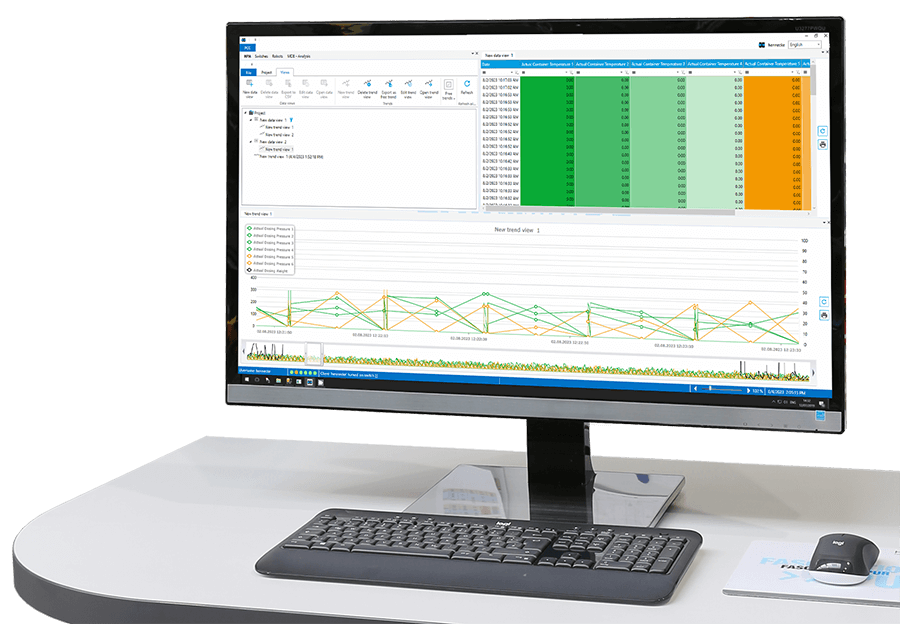

- System visualization: Flow-diagram-based visualization of rotary table or oval system layouts, ensuring operators always have an overview of ongoing processes.

- Robot module: Creation, editing, and transfer of motion paths directly within the software.

- Part tracking: Real-time monitoring of produced quantities per mold; automatic shutdown of the respective position when target quantities are reached.

- Non-production option: Controllable idle cycles or non-production phases can be planned without risking material loss.

Customer benefits at a glance

- Efficient process monitoring and targeted optimization

- Fast, intuitive commissioning with reduced training requirements

- Suitable for highly automated systems with robot integration

- Prevention of overproduction through automated quantity monitoring

- Savings in raw materials and production capacity through targeted process control