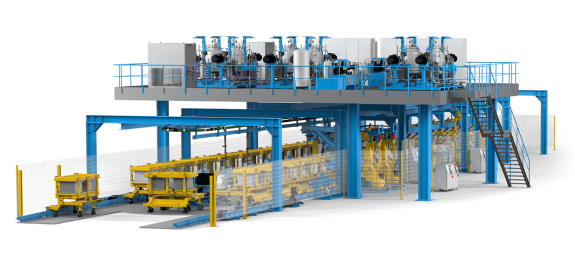

WKH systems

Hennecke's WKH oval conveyors use an oval transport system. The main area of application is the production of PU foam parts for car seating and head and backrests. Smaller parts as well as other products from different fields of application can also be made with the flexible WKH systems technology. Because processors are often confronted with the challenge of using different formulations for a whole range of products depending on the manufacturer and type of car and because the number of seating variations is increasing steadily, a mold change is often required. Hennecke’s oval conveyors are appropriate here especially because they have an automated in and outfeed station (QCD or ECD system) which enables the exchange of mold carriers during production and at a conveyor speed of up to 15 m/min.