PUR-CSM SKIN lines

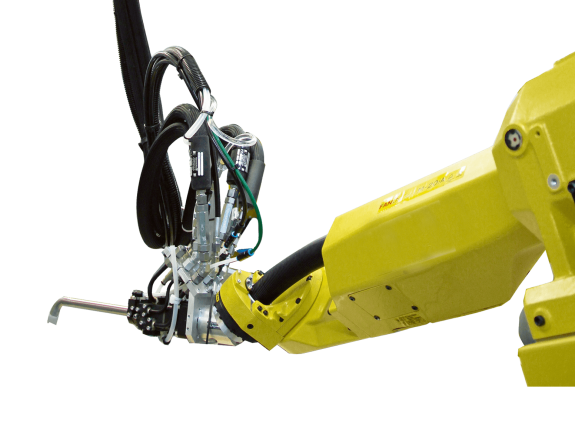

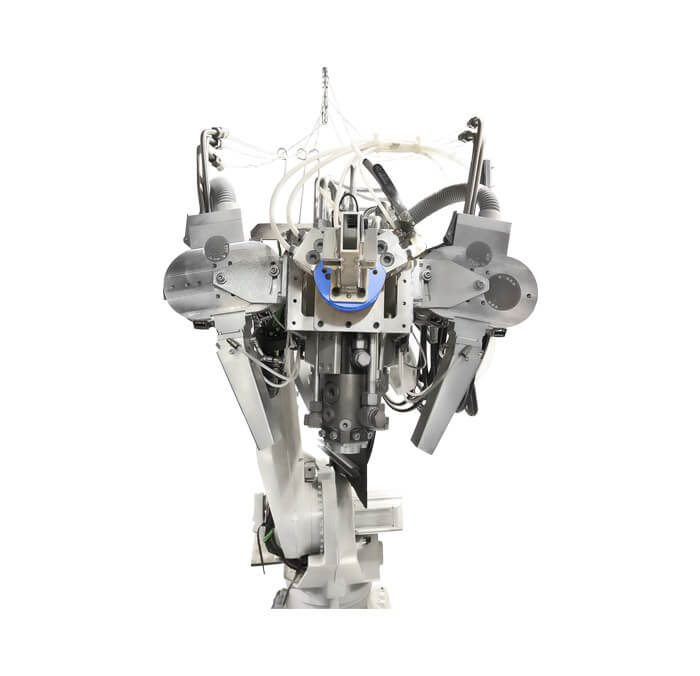

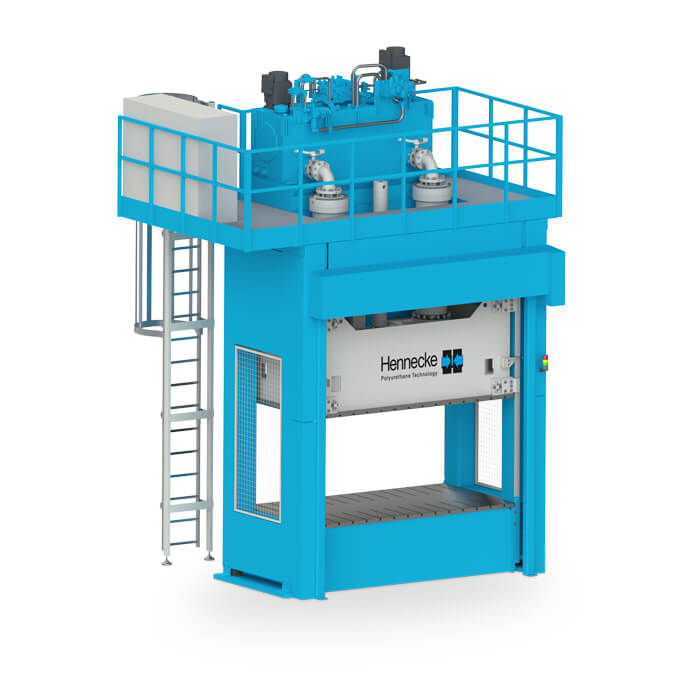

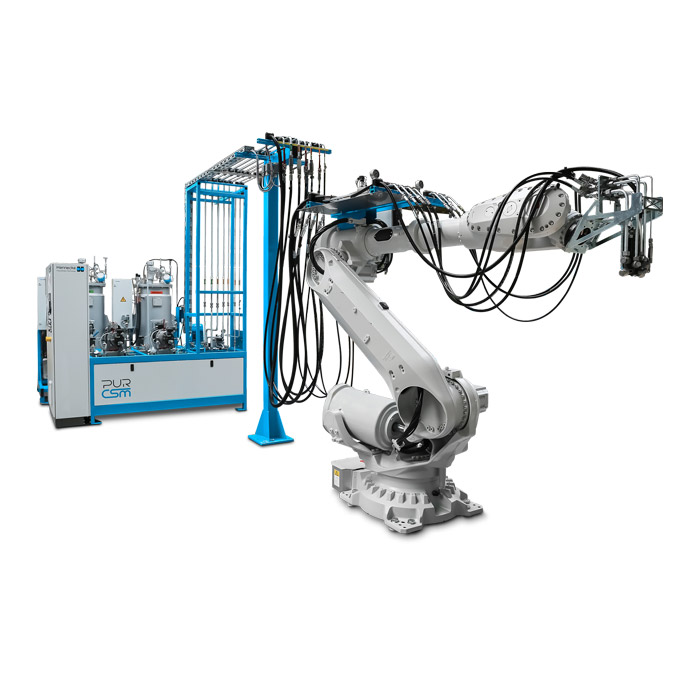

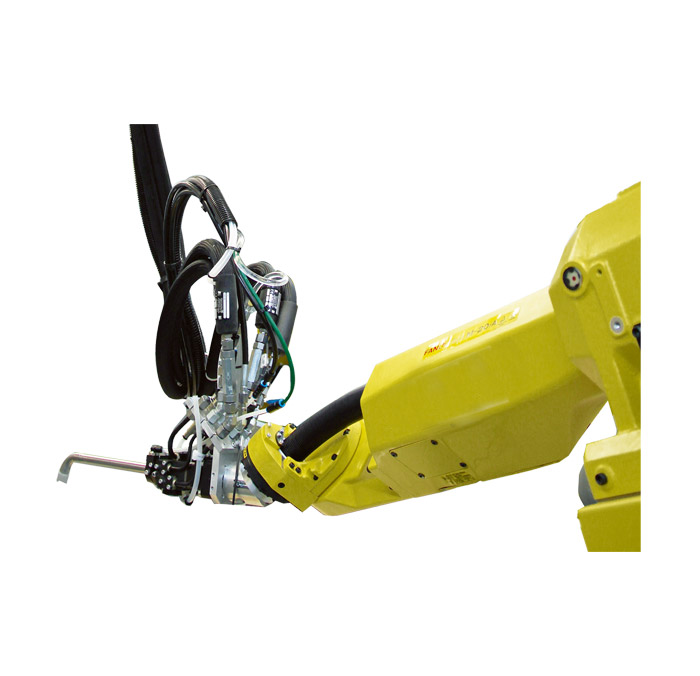

The benefits of spray technology will pay off especially when it comes to finishing complex parts such as dashboards or door panels. A layer of aliphatic paint is initially applied by In-Mould Coating (IMC). This UV-resistant coating is then reinforced with a sprayed aromatic polyurethane. Compared to PVC, this combination exhibits greatly improved haptic properties and extremely low emission values. As the coating will only be applied where needed, up to 10% material savings can be achieved. Thus, spray skin is not only one of the most top-grade surface technologies, it is also very attractive in terms of cost. In addition, the user will achieve a reduced specific density at the same skin thickness. Hennecke supplies tailor-made systems technology for PUR-CSM SKIN applications. Depending on the design, these lines are fully suitable for large-scale production.

Click here for accompanying documents in the PDF format

You will need Adobe® Reader® that you can download here for free.