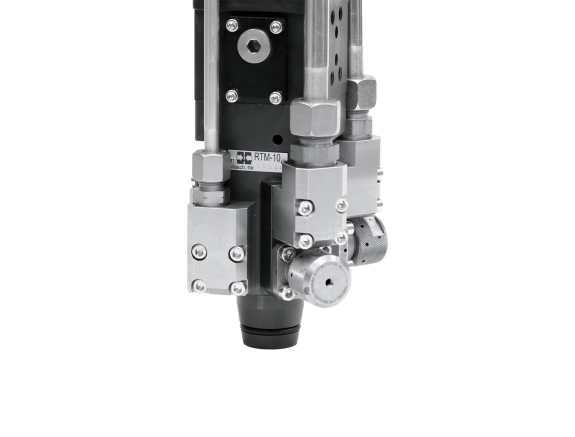

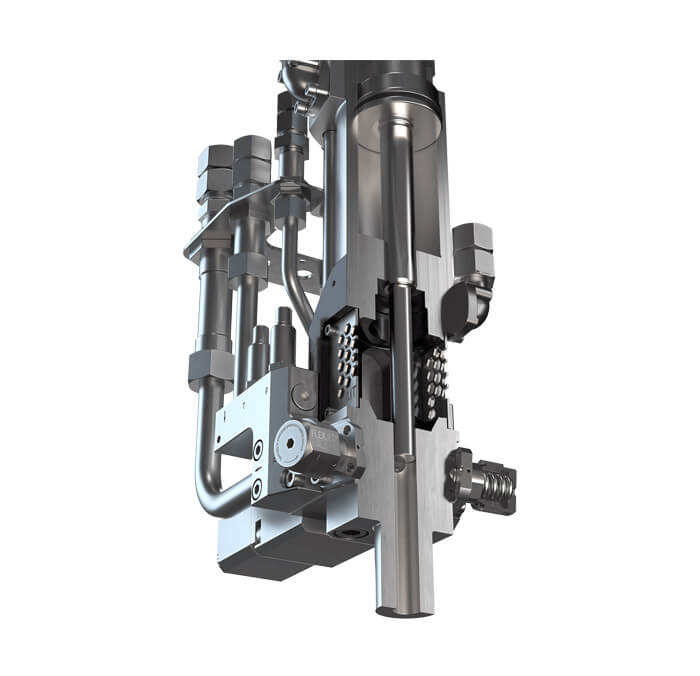

MN mixheads

Our MN linear mixheads operate on the groove-control principle. Due to their special parameters, they are particularly suitable for polyurethane spray-molding processes (PUR-CSM technology) and applications involving filled components. Hennecke's lineup of 2- to 4-component MN mixheads covers a vast spectrum of outputs, ranging from 6 cm³/s to 10,000 cm³/s. For CSM spray applications, users can optionally add 'smart' MN accessories such as a spraying lance for complex mold geometries or a high-performance cutter for a metered addition of glass fibers. Moreover, MN mixheads are ideal for attachment and thus suited for all RIM and RRIM processes. MN mixheads are optionally available with Hennecke constant pressure injectors which maintain a virtually constant mixing pressure over a wide operating range. Output changes can thus be effected without injector adjustment. At the same time, the application range of the mixhead is effectively expanded.

Click here for accompanying documents in the PDF format

You will need Adobe® Reader® that you can download here for free.