Hennecke mixhead technology

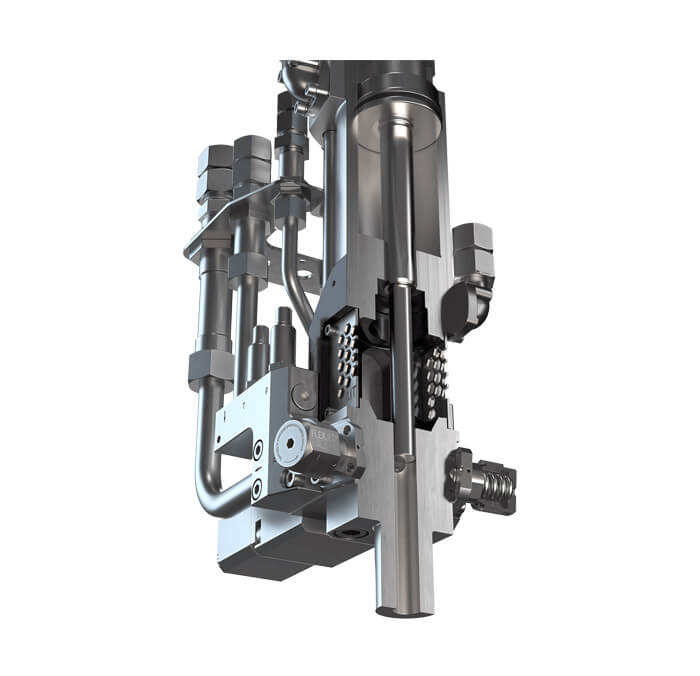

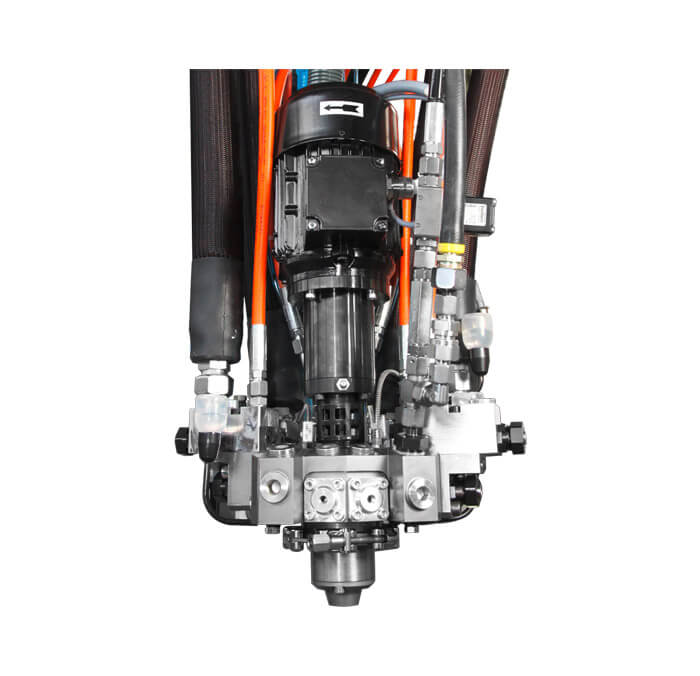

One key factor that ensures high-quality and efficient processing of polyurethane is mixhead technology. The development and manufacture of high-pressure mixheads requires a great deal of know-how and many years of experience. Hennecke has outstanding expertise in this area and makes its mixheads (apart from a few standard parts) in its own manufacturing halls. This is a novelty in the European competitive market. It is also the reason why many leading PU processors prefer mixheads from Hennecke. They know from experience that the high-quality design pays off in the production process.

High-pressure mixheads made by Hennecke

Making a profit with high pressure

Whether rigid or flexible, integral skin, filling or energy-absorbing foam is concerned, Hennecke has the appropriate high-pressure polyurethane mixhead for almost every application that requires mixing based on the impingement injection principle, from standard to specific applications. Variable sizes and injector shapes as well as a comprehensive range of accessories ensure that the mixheads can be adapted to suit a great variety of conceivable requirements - including yours!

All high-pressure mixheads at a glance

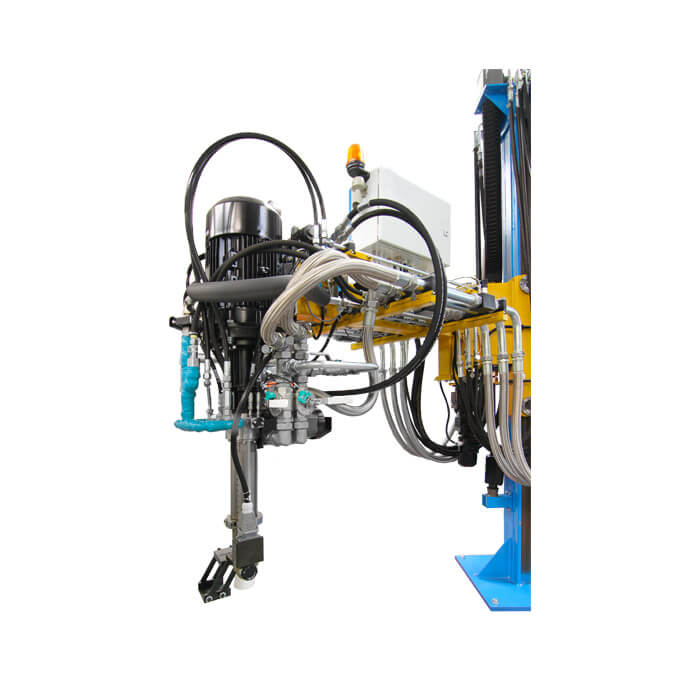

Low-pressure mixheads from Hennecke

Always striking.

Various raw materials and applications make mixing using impingement injection impossible. This is the case, for example, when casting systems or high-viscosity components are used. For many reactive components and additives - e.g., in continuous slabstock lines - mixheads are fitted with special stirrers to ensure that the reactive systems and additives are mixed homogeneously in the mixing chamber and a laminar output is achieved. To a certain extent, processors can influence factors such as the cell structure and cell size of foaming systems by means of particular types of stirrer. High-strength stirrers are used in compact and cellular elastomer systems, ensuring optimal results even when the processing parameters are extremely difficult.

Click here for accompanying documents in the PDF format

You will need Adobe® Reader® that you can download here for free.