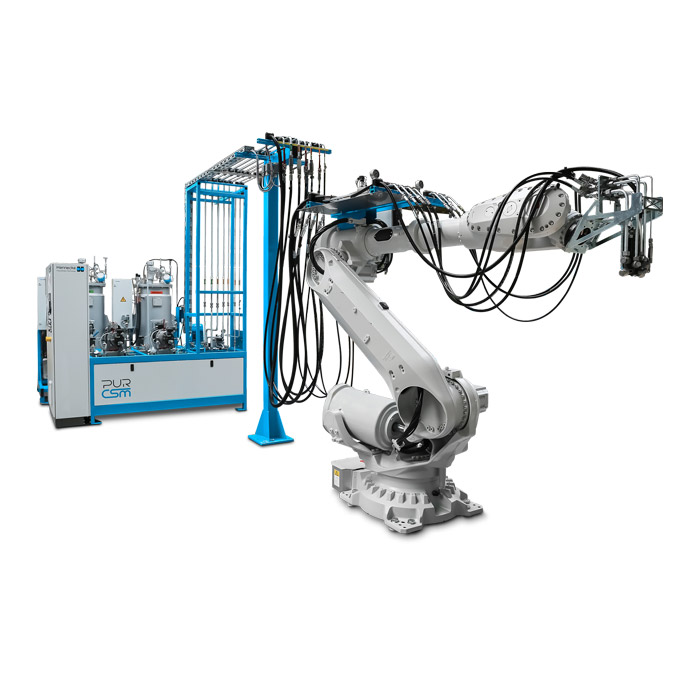

Spray application lines

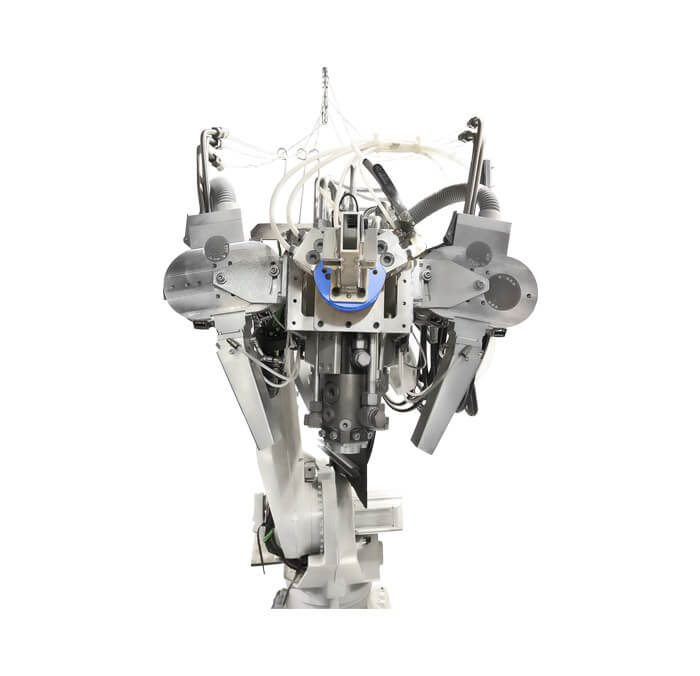

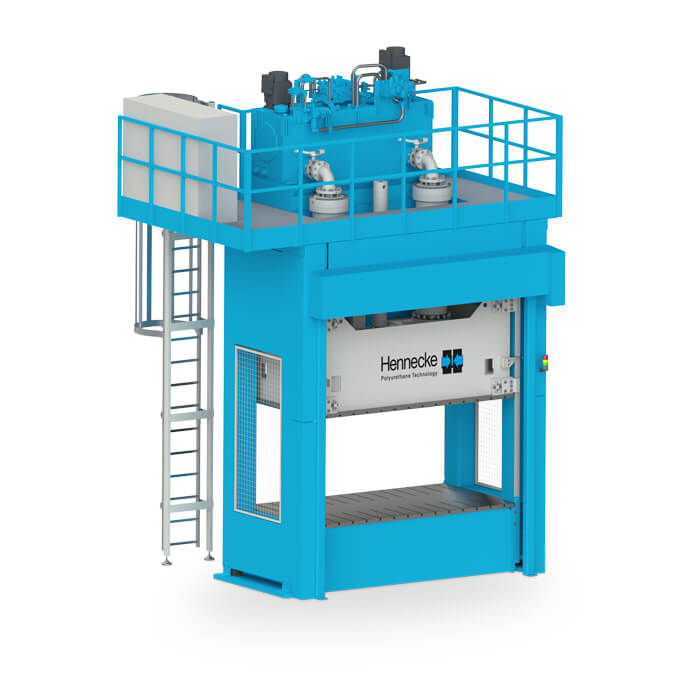

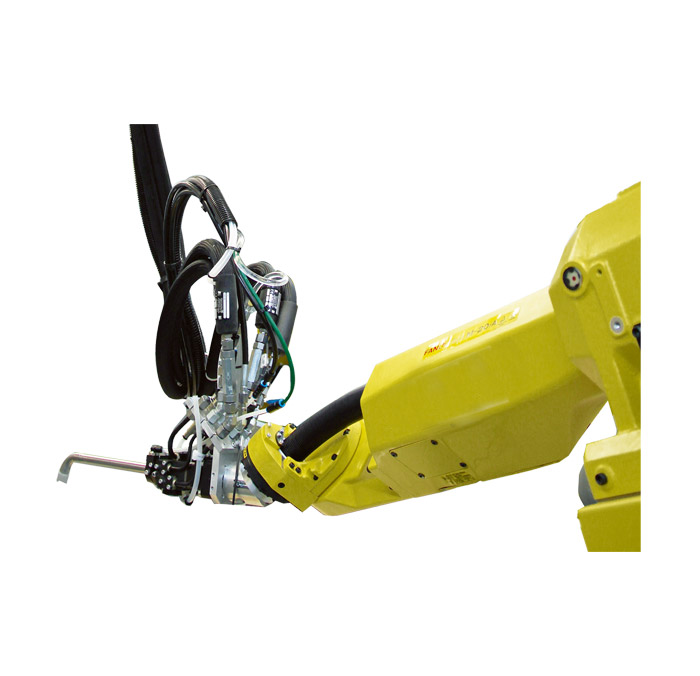

The innovative and forward-looking PUR-CSM polyurethane spray-moulding technology has been successful in practical use for over fifteen years now, setting new standards in PU processing ever since – whether in special-purpose applications or mass production. Among users, PUR-CSM has become synonymous with efficiency, flexibility and process reliability. Supplementing the engineering portfolio of advanced spray technology, customized mixheads have been developed along with various high-efficiency processing cells and machine designs. Together, these solutions provide suitable configurations for small and large production volumes and are tailored to fit the requirements of spray technology and its special parameters.